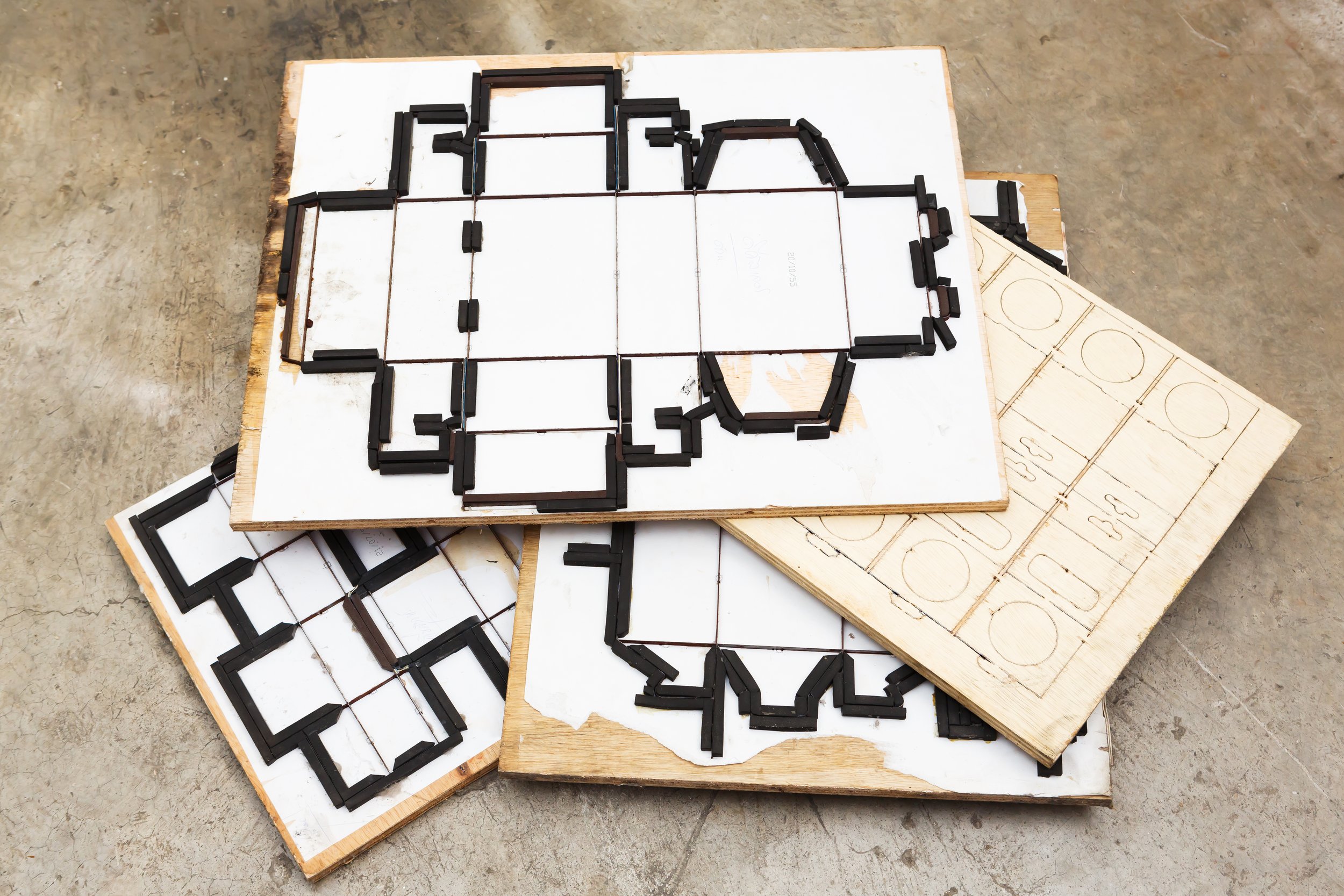

Die Cutting, Forming & Gluing

The Unparalleled Advantages of Die Cut Packaging

Customized packaging stands out on crowded shelves. Distinctive shapes and designs from die cutting make products recognizable and attract customers. Everett Graphics packaging can be tailored to fit your product and offers excellent protection.

Tray forming (including clamshell lids)

Peel & Seal

Cold glue & Hot melt

Capabilities

Windowing

M-Tak tape

Custom Construction

Auto bottom

Peel & Seal

Stikem (Fly Traps)

Trays (w/lid, corrugated or plastic)

Carton Styles

Straight Line

Double Straight line

4 Corner Biers Tray

6 Corner Biers Tray

Clamshell Trays

Child Resistant Packaging (CRP)

100% of the reclaimed material from die cutting is recycled.

Die cut packaging not only looks good and works well but also supports cost-effective and eco-friendly business practices. Die cutting reduces material waste, lowering production costs and environmental impact. This aligns with the sustainable packaging goals of Everett Graphics, boosting your brand's appeal.

What is die cutting?

Die cutting is a manufacturing process used to cut specific shapes and designs from various materials, such as paper and cardboard, using a specialized tool known as a die. The die is typically made of steel and is designed to create a clean, precise cut, which can be used for a variety of applications, including packaging, crafting, and product design. This method allows for high-volume production of consistently shaped items and can accommodate intricate designs that would be difficult to achieve with traditional cutting methods. Die cutting is an efficient way to produce customized boxes and decorative elements.